History

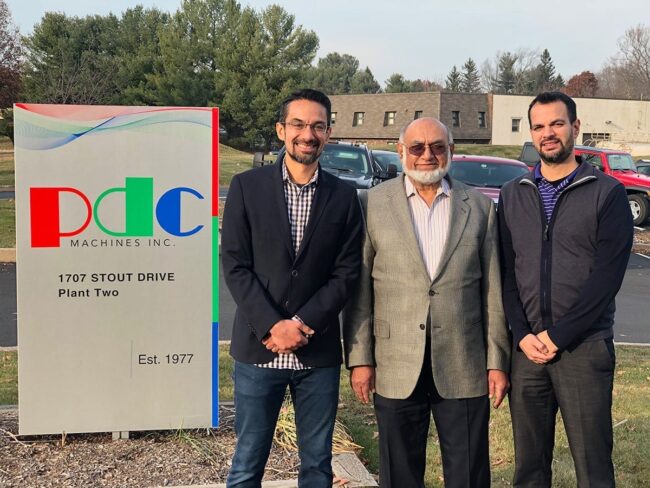

PDC Machines was founded by Sy Afzal after emigrating from India. Educated at Princeton University, Sy took PDC Machines from a modest suburban business to a leading provider of diaphragm compression technology for a world market of industrial and specialty gas producers and suppliers, a variety of industrial end use markets, and the emerging hydrogen energy sector. Through a comprehensive blend of robust machinery, thoughtful and precise engineering, and a deep-rooted commitment to customer support, PDC has grown into a world leader in compression equipment and hydrogen refueling technology.

PDC’s industrial engineering side serves customers of specialty gas filling plants for helium cylinder, welding gas, and semiconductor applications. Their hydrogen energy segment has a focus on the movement of people and goods around a world economy with zero emissions, positioning PDC for continued growth and scale. PDC’s goal in hydrogen is to promote a green future of sustainable cars, busses, drones, forklifts, all sizes of trucks, and green energy storage.

Generating Loyalty on a Global Scale

PDC believes in its culture. Its commitment to quality in its wide product portfolio and its industry renowned customer support ensures loyalty and trust from customers. PDC’s insistence on serving the market with humility, empathy, and an eye towards building partnerships has enabled much of its success thus far.

The firm’s long-standing experience in the hydrogen market has brought brand equity across all economies in the world. PDC Machines has supplied equipment for high-profile events and companies the world over, such as Toyota, the Philadelphia Eagles, market-first hydrogen stations, and compressors for two bus refueling stations for the upcoming Tokyo Olympics. With reliable equipment that “just works when it should,” PDC is known in the industry as a brand to trust. In Vice President Kareem Afzal’s words, “Our ability to scale operations to meet demand has also been a key driver. Our customers are driven to make hydrogen a ubiquitous fuel along with conventional fuels and we are committed to making that happen.”

Industry Challenges and COVID-19’s Impact

Prior to COVID, PDC maintained its leadership in the industry with innovative new technologies while also forecasting the market landscape 5-10 years out and investing in green hydrogen energy. By remaining close to clients and anticipating need, PDC was able to continue investing in highly technical, skilled talent, all while scaling its production and industry reach.

COVID-19, as it has for virtually every industry, changed the nature of these challenges, and required a shift in thinking to address them. “Encouraging a career shift of the right talent in the middle of a pandemic can be a big ask for someone and their family. We have done well on this front, but always can do better,” said Afzal.

PDC came up with a fast and unique solution for one of its most pressing challenges this year, staying connected to customers and prospects to share information on a highly involved product. Prior to lockdown, PDC representatives were able to travel directly to clients to demonstrate the quality of its equipment. Suddenly, this became an impossibility, and with clients from Germany to South Korea, PDC needed to find another solution. They produced their own series of webinars early in the pandemic that were short, to the point, and on topics of interest to the customer. They have experienced incredible engagement and a continual stream of new orders through the tactic, with a captive audience of attendees from worldwide sectors. Part of that success comes from customizing their approach to meet customers where they are, using WeChat for webinars in China, Line in Japan, and Kakaotalk in Korea.

.jpg)

PDC Culture

PDC values each employee as part of the PDC business family. The first two employees are still part of the firm today, and each employee is committed to the vision of realizing human potential through robust hydrogen infrastructure. This is true across every office at PDC, including teams in Shanghai, Kyoto, Seoul, and Munich. “While no one is perfect, PDC will work to ensure that the customers end goals are met with our support. We all want to see a present and future where zero emissions technology is at the heart of society, and our product will fuel that future,” said Afzal.

With localized production practices and international reach, PDC has created skilled jobs for the Philadelphia area and worldwide, all while generating rapport with customers through reliable products and devoted customer service. Summing up their commitment to employees and supply chain partners in a word, “loyalty.”

The Future of Energy

PDC is positioned for continued growth in 2021 powered by the transformative opportunities of hydrogen energy. They plan to enter some countries with direct sales and service offices and hopefully begin traveling again as safety precautions allow. The firm sees another opportunity from the lockdowns though: governments worldwide have taken notice of their environments during this period of lockdown, which makes this moment of crisis one of potential for clean energy as well. Green energy is one potential vector for both economic recovery from COVID and ecological recovery from previous emissions practices. This shift in world public policy creates opportunities for companies like PDC that can help enable zero emissions mobility and a wave of high paying jobs to power society for generations to come.

When asked what advice he has for other middle market executives looking to grow their business, Afzal shared, “Not to sound cliché, but adaptability and flexibility are the name of the game now and perhaps forever. From how we approach talent for engineering positions to how our organization connects with customers or provides support for our equipment, we’ve become increasingly flexible and thrive by meeting the new needs of this changed world.” PDC Machines has begun offering flexible work and location policies for jobs that used to be entirely in the office and has even moved some of its more traditional facilities, like those in Japan, to a work from home environment.