Wiegel Tool Works: An Heirloom

Wiegel Tool Works, labeled as an elite metal fabrication manufacturer with an emphasis in precision stamping, is the result of a history of the hard-working and innovative Wiegel family. The success of this company all started on December 6th, 1941, when Otto Wiegel founded Wiegel Tool Works (WTW) as a tool & die company in Chicago, IL. In the 1950’s, WTW moved to Franklin Park, IL. In 1968, shortly after the startup, Otto’s son Martin Wiegel joined forces with his father in an attempt to grow the business. Martin graduated from Purdue University with a Bachelor of Science in Industrial Engineering and proceeded to join the Navy where he served four tours of duty in Vietnam on the USS Princeton. His most prevalent contribution to the company was investing into stamping equipment, which kickstarted the company’s growth. In 1978, WTW moved from Franklin Park to Wood Dale, IL.

In 2001, Martin’s eldest son Aaron Wiegel became the next family member to contribute to WTW’s growth. After graduating from Northern Illinois University with a bachelor’s degree in Engineering Technology, Aaron became the Vice President of Stamping. This position gave him the opportunity to oversee quality and tool repair, which sparked investment in advanced computer software systems, including state of the art ERP systems. Two years later, Martin’s daughter Erica Wiegel joined the company. Erica took charge of WTW’s prototype department with her knowledge in Industrial Engineering. In this position, she was able to expand WTW’s capabilities and helped customers develop concepts into production components. Next, in 2009, Martin’s youngest son Ryan Wiegel brought his knowledge of Communications from Western Illinois University to become the VP of Operations. With his expertise, Ryan led all machine acquisitions and enhancement of current and new production equipment.

In 2011, Martin Wiegel sold the evolved business to his three children. Under their care, WTW substantially expanded through the purchase of new facilities to aid in the manufacturing, shipping and warehousing capabilities. Today, WTW occupies a total of 207,000 square feet over four different facilities. This 80-year history consisting of a third-generation family atmosphere contributes to a strong and consistent culture among each of the four locations. This special relationship bonds employees together and motivates everyone to work hard for each other to generate the company’s continued success.

Pictured above is Aaron Wiegel, president and owner of Wiegel Tool Works. He stands in front of WTW's Minster Servo Press, one of their newer stamping technologies.

A Manufacturing Leader

Although metal stamping continues to be a highly competitive business, WTW sets itself apart by offering more options in metal stamping capabilities such as in-house engineering, prototyping, building and maintaining progressive tools, high-speed and heavy metal stamping and integrating components into finished assemblies, and comprehensive, multi-part systems. The offerings do not stop here. As WTW continues to grow, their manufacturing capabilities are expanding into advances in sensor and vision system technology to monitor manufacturing processes and provide top-quality parts. With an ultimate goal of satisfying customer needs, WTW began to invest in the expansion of other capabilities such as automation equipment and robotics to increase efficiency, improve quality, and expand its market size and scope.

Although WTW specializes in the automotive industry, their manufacturing solutions are tapped into additional markets including the medical, electrical, appliance, lighting, aerospace, electric vehicle, structural building component, solar, military and defense, insert and injection molding, and packaging industries. WTW continues to review quality standards and certifications in order to have world-class practices and procedures to be able to supply and provide manufacturing solutions to any industry. Not only is WTW expanding their services, but they also plan on expanding their footprint outside of Chicago to offer more customers a full, turn-key solution to their projects.

In an attempt to keep up with the ever-evolving world of manufacturing and to share insight with the market, WTW is involved with five different trade organizations: The Technology and Manufacturing Association, Chicagoland Chamber of Commerce, Illinois Manufacturers’ Association, Precision Metalforming Association, and the National Association of Manufacturers. Being involved in the community keeps WTW relevant and knowledgeable about the industry’s status.

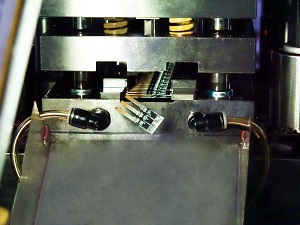

This picture shows WTW stamping a precision terminal part, which they are producing in one of their progressive die high-speed metal stamping presses.

Investing in Human Capital

Ensuring that WTW provides top-quality parts, an exceptional staff is the key to success in maintaining the company’s status as a leader in the world of manufacturing. As many companies that provide any type of service know, quality customer service and attentiveness is what keeps the consumer coming back. Therefore, WTW is constantly reinvesting in human capital through their use of both internal training as well as external education.

Among the training programs WTW has, the company highlights its world-class tool & die apprenticeship training program that is certified through the Department of Labor. This program encompasses 10,000 hours of on-the-floor training in addition to three years of external training at the Technology & Manufacturing Association. With the combination of both internal and external training, WTW is able to excel in innovation thought leadership, resulting in new and exciting ideas that are implemented throughout their organization. With a goal of providing top-notch service to the customer base, WTW believes that “having and maintaining a culture of excellence is [their] recipe for success”.

Wiegel Tool Works Words of Wisdom

After 80 years of learning, growing, and building success, WTW has learned a very simple but important fact: you get out what you put in. WTW treats their company as a hobby that they are fortunate enough to get paid for. Through creating a powerful culture among employees through family ties and mindful hires, WTW has learned that transparency through communication and consistency are the key drivers to advancement. By maintaining a passion for their business, their processes, and the people they work with, success in the company continues to flourish.

Secondly, the key to success in any business is metrics. You cannot manage what you cannot measure. Measuring success allows employees to understand what they are working towards. Where sections falter, management needs to provide the necessary support in different aspects in order to bring the metrics back to the goals set forth.

Having these two points established in their business has positioned WTW in their impressive reputation today, and they truly believe that the tactics they keep consistent throughout their existence will be helpful in catalyzing success in other middle market businesses as well.